The demand for excellence

Processes and certifications

Quality is our top priority!

The quality management system is the cornerstone of the Protec Group’s operations. Compliance with ISO 9001, EN 9100 and PRI NADCAP requirements is at the heart of our management system.

Quality activities

Quality management

The growing recognition of our quality system by the world’s leading contractors confirms the effectiveness of our management. The control and monitoring of our processes are applied in four areas:

Customer satisfaction thanks to our skills :

Listening, to better understand customer needs and respond effectively.

Technical assistance, to offer solutions that address specific needs.

Produce and deliver a product that meets the customer’s specifications, within the agreed timeframe.

Developing the knowledge and skills of our employees

To implement all our special processes according to best practices, in complete safety and in full compliance with our clients’ requirements.

Continuous improvement of our processes

By constantly analyzing their indicators, identifying risks

and opportunities.

In this way, we anticipate future needs to maintain our competitiveness.

Compliance with environmental and safety requirements

which guarantees the continuity of our business. Our relationships with our customers, contractors, external service providers and employees are built for the long term.

This policy is deployed uniformly across all production sites. Regular audits are carried out to identify and implement areas for improvement in our processes.

ISO9001/EN9100 certificates

NADCAP NDT PI

NADCAP CP PI

NADCAP NDT PSI

NADCAP CP PSI

NADCAP CP PM

Other documents for PROTEC Group service providers

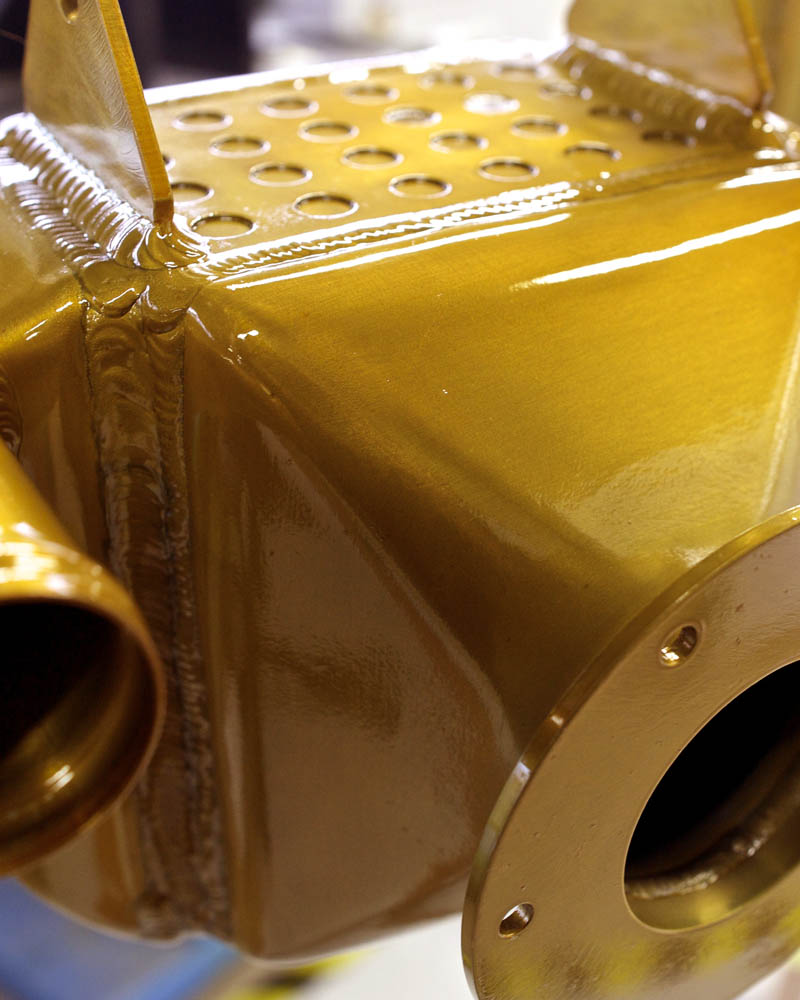

Product quality

We guarantee compliance with requirements by deploying robust, repeatable processes, tracking all indicators at every stage, and carrying out rigorous checks on every order released.

to meet our customers’ requirements.

working closely with our various workshops, provides essential technical solutions for carrying out a wide range of treatments on all types of parts.

each specialized in its own field (material health, surface preparation, electroplating, oxidation, painting) guarantee the conformity of delivered products.

Special processes

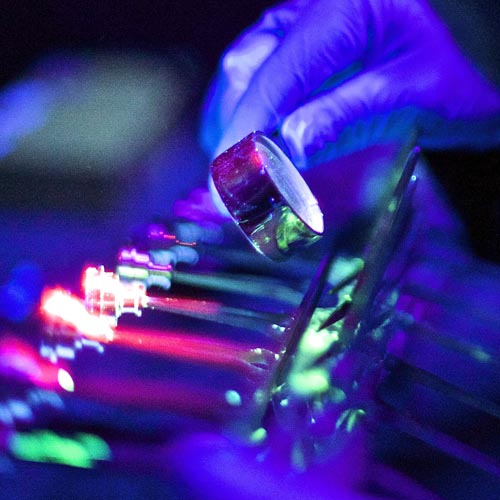

The Protec group is a major player in Special Processes, particularly in material health control and surface treatments.

Technical expertise

The results of a Special Process cannot be fully verified a posteriori by inspection or testing of the product; the consequence of deficiencies in implementation can only become apparent when the product is in use. Their implementation therefore requires technical expertise and specific periodic monitoring of these processes.

Our quality teams, working closely with our Research & Development department, define, optimize and qualify numerous special processes for prime contractors in the aeronautics, defense, space, rail, energy and luxury industries.

Rigorous practices

The implementation of a special process is systematically preceded by a rigorous qualification process, which involves the validation of installations, procedures and personnel qualification by the prime contractors.

Qualified processes, according to our entities, are identified by means of a capacity list, listing all treatments according to technical reference specifications and the prime contractors concerned.

All our certifications and accreditations

Find the list of contractors and all certifications. You can download the documents.