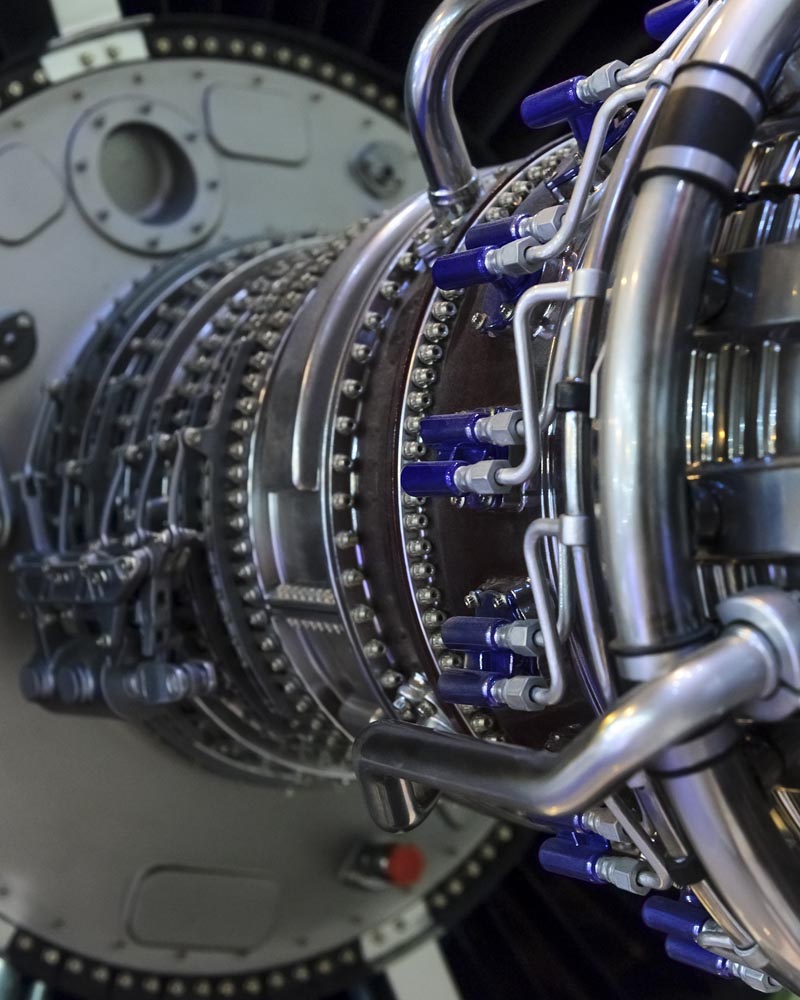

Aviation, defense and space

Trust at its peak

Our Protec Aérospace division specializes in the processing of materials for the aerospace, defense and space industries, as well as for sectors requiring the highest technical performance, such as energy and railways.

For over 75 years, we have been meeting our customers’ expectations in terms of reliability, service and innovation. We take charge of their most critical equipment, from airliners and fighter jets to defense systems, satellite constellations and nuclear power plants.

Know-how to improve our customers’ performance

The Aerospace Division offers the highest levels of reliability and technical performance. As a leader in materials processing, we provide our customers’ equipment with first-rate anti-corrosion, mechanical, electrical and detection properties.

This uncompromising pursuit has enabled us to develop a unique expertise within the French industry, combining recognized skills with the most advanced materials processing technologies. This expertise includes environment protection by minimizing the impact of our chemical and electrolytic treatment processes.

A versatile industrial infrastructure

in a rapidly growing sector, our customers in the aerospace, defense and space industries are looking for reliable partners with strong production capacity, short lead times and effective business continuity plans to manage the industrial risks inherent to material treatment activities.

Drawing on its experience, the Protec group has built up an industrial infrastructure that meets these expectations.

Through our four production sites, we offer an industrial network that is:

20 M€ investment in industrial facilities between 2021 and 2023, to increase our surface treatment capacities, particularly for galvanizing and oxidizing.

Although versatile, our 4 sites have unique specialties enabling us to offer short circuits to our customers: mass production oxidation, mineral oxidation or black chrome.

Each site meets the highest environmental and fire safety standards. The redundancy of capabilities across our different sites enhances our agility and allows us to offer multiple solutions to each of our clients.

Our services

Personalized support

Thanks to our sales teams and technical experts, we’re able to accompany our customers and provide customized technical solutions for specific performance requirements.. We offer a wide range of standard surface treatments, as well as customized solutions.

The widest range of material treatments in the aerospace industry

Our special processes cover all specifications for aeronautical, defense and space equipment.

- Penetrant testing S2 and S3

- LF magnetoscopy

- Nital attack

- Macrographic attack

- Inconel pickling

- Titanium blasting

- Radiography

Our 10 COSAC Level 1 to 3 qualified inspectors in penetrant testing and magnetic particle inspection ensure the conformity of your products.

- Chromating with or without hexavalent chromium Alodine 1200

- Surtec 650

- Lanthanum 613.3

- TCS PACS

- Chemical and electrolytic deposits on plastics and composites

- Silver plating

- Framing

- Copper plating

- Gilding

- Tinning

- Surfaced tinning

- Chemical nickel plating

- Electrolytic nickel plating

- Black nickel

- Zinc plating

- Electrolytic polishing treatments

- Anodic sulfuric oxidation (ASO)

- Fine anodic sulfuric oxidation (fine ASO)

- OAS New Generation (OAS NG)

- Anodic sulfo-tartaric oxidation (TSA)

- Long-cycle anodic sulfo-tartaric oxidation (TSA Long Cycle)

- Black mineral oxidation for space applications

- Sandblasting

- Bead-blasting

- Plastics media

- Savings

- Mechanical pick-ups

- Laser marking

- Epoxy paints

- Polyurethanes

- Multi-layer aeronautical systems

- Armament and railways

- Waterborne paint

- Hammered paint

- Vermiculated

- Grained finish

- Anti-slip

- Special paints and varnishes

Within the group, we have 8 paint booths to aeronautical standards.

Tailor-made solutions

We offer expertise and the development of tailored solutions, with on-site support and direct management of operations.

We recruit and train diverse profiles with cutting-edge skills.

Keeping knowledge alive

Protec, a brand with a diploma

The Protec Group has set up PRO SCHOOL, an on-site training center, for its own internal needs and those of its partners, to ensure that expertise is passed on. We offer a wide range of training courses in the fields of materials treatment and special processes.