Our business lines

French production

French know-how at the service of quality

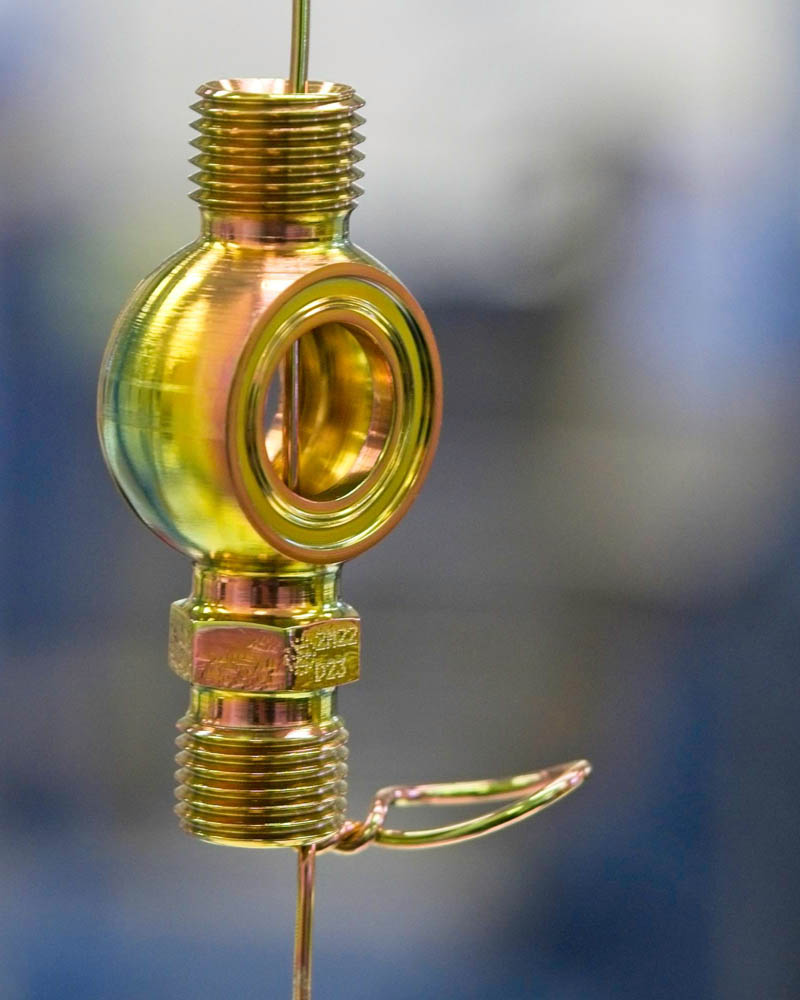

From mass production to one-off parts and from standard treatments to the most complex processes, the Protec group delivers French-made solutions with a strong commitment to quality.

We offer expertise and state-of-the-art solutions for all your surface treatment and decorative finishing needs.

Our services and expertise

Our expertise is second to none

Four fundamental commitments are the driving forces behind the Group’s excellence, the pillars of our performance and long term success.

Cutting-edge technical expertise

Multi-treatment of parts with complex geometries

Selective treatment

High-thickness deposits

Efficient supply chain management

A systematic continuous improvement process

The company’s strategy relies on the best skills, processes, practices and tools to manage the Supply Chain and achieve our performance objectives:

based on analysis of HSE, OQD, OTD and productivity indicators for all production sectors

based on work-in-progress and forecasts provided by customers

are held on a regular basis

Research & Development

Innovation in our DNA

Innovation is a key priority in our sectors, enabling us to keep up with our customers’ technological advances, meet environmental challenges, enhance our competitiveness and adopt new processes.

Our R&D department is an agile organization, serving both today’s business and preparing for the future.

- Chemical conversion without Cr(VI)

- Fine sulfuric anodizing

- Sulfo-tartaric anodizing

- Cr(VI)-free pickling

- Sulfuric anodizing for new-generation colors (black, red and yellow…)

- Metallic coatings to replace decorative chrome plating and black chrome plating.

- Hard anodic oxidation

- Colored chemical conversions on metallic coatings Zinc and cadmium

- Very thick metal deposits

- Chemical metal deposition on miniaturized parts

- Zn-Ni process

- Anaphoresis

- Metallization of non-metallic materials (plastics, composites, ceramics)

- Electrolytic and chemical polishing of additive manufacturing parts